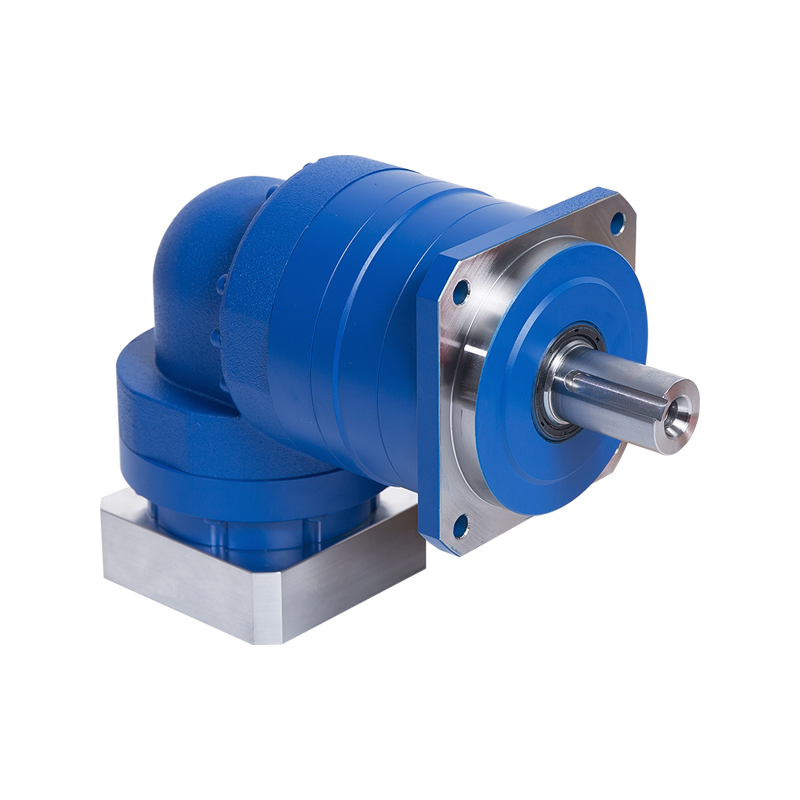

Servo Motor MKT Precision Planetary Reducer

Cat:MK series planetary reducer

Meet the needs of customers with high precision requirements for semiconductor devices, automation equipment, machine tools, etc.Applicable to: Door d...

See DetailsWhen selecting a planetary gear reducer for a specific application, several key factors should be considered:

Torque Requirements:

Maximum Torque: Ensure the reducer can handle the maximum torque your application will generate.

Continuous vs. Peak Torque: Consider both continuous and peak torque requirements, as the reducer must withstand peak loads without damage.

Gear Ratio:

Desired Gear Ratio: Determine the required gear ratio to achieve the desired output speed and torque. Planetary gear reducers offer a wide range of gear ratios, which can affect performance and efficiency.

Speed:

Input and Output Speeds: Match the input and output speeds with your application’s requirements. Ensure the reducer can operate efficiently at these speeds.

Efficiency:

Power Losses: Consider the efficiency of the gear reducer, as higher efficiency reduces power losses and improves overall performance.

Size and Weight:

Space Constraints: Evaluate the physical size and weight of the reducer to ensure it fits within the space constraints of your application.

Load Capacity: Make sure the size and weight do not compromise the load capacity of the gear reducer.

Durability and Reliability:

Material and Construction: Check the materials and construction quality to ensure long-term durability and reliability under your operating conditions.

Environmental Conditions: Consider factors such as temperature, humidity, and exposure to contaminants, and select a reducer that can withstand these conditions.

Backlash:

Accuracy Requirements: If precise positioning is required, choose a reducer with minimal backlash. High precision applications demand reducers with low backlash.

Lubrication and Maintenance:

Lubrication Type: Understand the lubrication requirements and maintenance schedules. Choose a reducer with lubrication needs that fit your maintenance capabilities.

Service Life: Evaluate the expected service life and maintenance requirements to ensure they align with your application’s needs.

Load Characteristics:

Type of Load: Consider the nature of the load (e.g., constant, variable, shock loads) and select a reducer that can handle these conditions effectively.

Cost and Budget:

Cost vs. Performance: Balance cost with performance requirements. Sometimes a higher upfront cost may result in lower overall operational costs due to better efficiency and durability.

Mounting and Integration:

Compatibility: Ensure the reducer’s mounting options and shaft configurations are compatible with your application’s design and integration requirements.

Noise and Vibration:

Operating Environment: If noise and vibration are concerns, select a gear reducer designed to minimize these issues.

By carefully evaluating these factors, you can select a planetary gear reducer that meets your application’s specific requirements and ensures optimal performance and reliability.