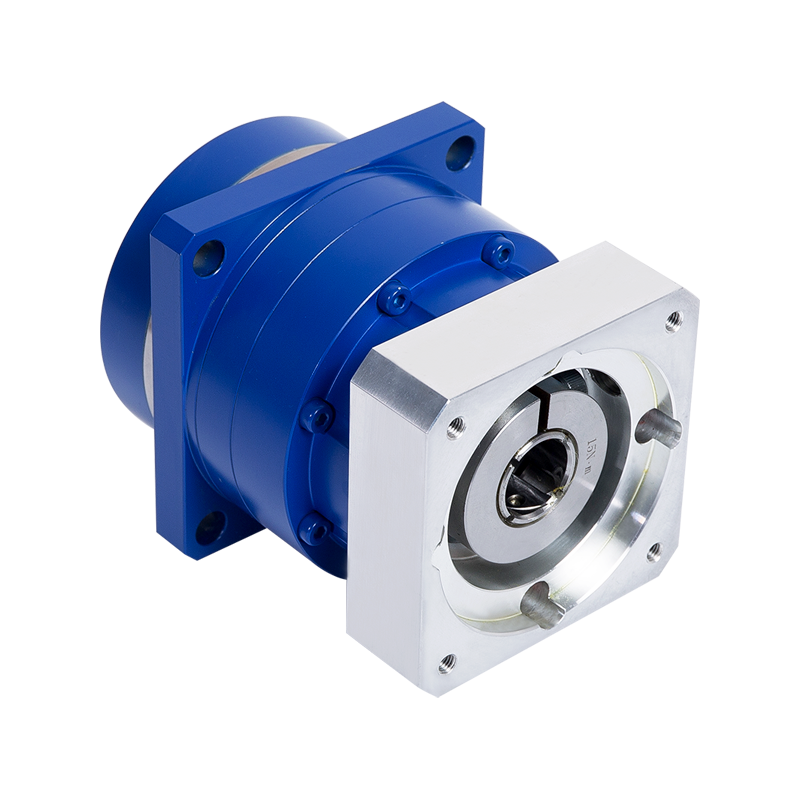

Door Driving Precision Planetary Reducer

Cat:MK series planetary reducer

Industry-product lineupApplicable to: Door drive (planetary, coaxial shaft)MKB Precision Planetary Reducer is a cutting-edge mechanical device designe...

See DetailsIn the world of mechanical engineering, precision planetary reducer play a crucial role in various applications ranging from robotics to aerospace. These components are known for their compact design and high torque capabilities. However, the load capacity of a precision planetary reducer significantly influences its performance and lifespan.

The Basics of Load Capacity

Load capacity refers to the maximum load that a precision planetary reducer can handle without experiencing failure or significant degradation in performance. This capacity is determined by several factors including the materials used, gear design, and lubrication methods. When a reducer operates within its specified load capacity, it functions optimally, allowing for smooth power transmission and efficient torque multiplication.

However, exceeding this load capacity can lead to premature wear and tear. A study by the American Gear Manufacturers Association (AGMA) indicates that operating a gear system beyond its load capacity can decrease its lifespan by up to 50%. This underscores the importance of understanding the load specifications when designing or choosing a planetary reducer for a specific application.

Performance Under Load

The performance of a precision planetary reducer is directly affected by its load capacity. When these reducers are subjected to loads within their capacity, they exhibit high efficiency, low backlash, and minimal heat generation, which are all critical for high-precision applications. On the other hand, when the load exceeds the rated capacity, issues such as increased friction, overheating, and potential gear failure can occur.

For instance, during high-stress applications, such as in robotic arms, a precision planetary reducer that is appropriately rated for the task will ensure that the robot operates smoothly, maintains accuracy, and avoids costly downtime. Engineers often recommend using a safety factor of 1.5 to 2 times the anticipated load to account for unexpected spikes in demand, thereby prolonging the reducer’s operational reliability.

Longevity and Maintenance Considerations

The lifespan of a precision planetary reducer is not solely contingent on its load capacity; it also depends on proper maintenance and operational practices. Regular lubrication, adherence to loads within specified limits, and the use of appropriate materials can significantly enhance the durability of these systems.

Moreover, when gearboxes operate within their load capacity, they experience less thermal stress, which contributes to longer service life. A well-maintained planetary reducer can last anywhere from 10,000 to 20,000 hours or more, depending on the application. Conversely, those subjected to excessive loads can fail within a fraction of that time, underscoring the importance of load management in prolonging lifespan.

The load capacity of precision planetary reducers is a foundational factor that influences both their performance and lifespan. Operating within the specified load limits not only ensures optimal efficiency but also helps in maintaining the longevity of the equipment. Engineers and designers must prioritize selecting the correct reducer for their applications, factoring in load capacity, and implementing regular maintenance practices. Understanding these dynamics will lead to better performance outcomes and reduced operational costs in the long run.